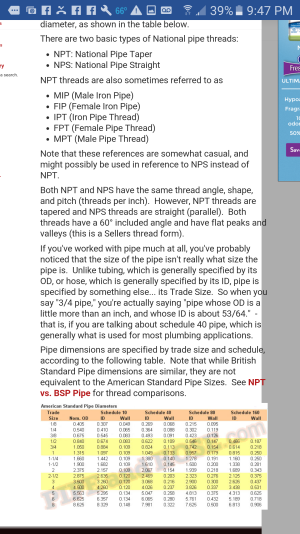

J

Johnny T.

Guest

Hello every one, I just feel that I can't help much with any airbrushing advice so maybe I can help by sharing my experience about what I know in setting up some of the compressor. Let me start by telling you about what I do for a living. As I stated before I'm a millwright journey man. For you that don't know what that is. We go by the term of the jack of all trade and master of none. We have been train in many blue collar jobs from a carpenter to a machines and much more. I'm one of the few people that enjoys there job. Because of the company that I work for. They have treated me pretty good. They have pay for all my schooling and training witch it was a five year to finish. Plus I have gotten pay wile doing so. Any way here is some pic and ill explains where I'm going with this.  This is a small part of where I work.

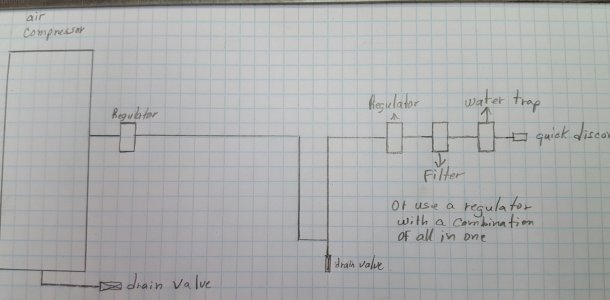

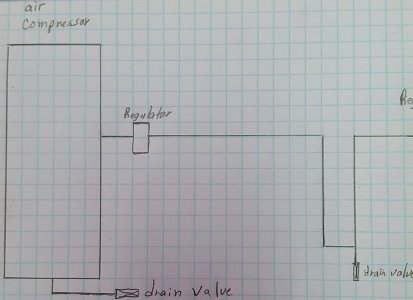

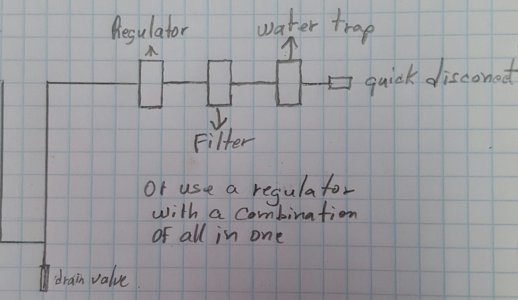

This is a small part of where I work.  This is one of the many air compressors that we have that supply air to the pneumatic equipment and valves. This compressor are rated at 300 psi. The reason that I'm telling you all of this is because I have seen some of the members asking about how to set up there compressor. And since I have some experience with this maybe I can share what I know with every one, this is my way of giving back to the community. So let's start by saying that we just got a new compressor and it is not set up for an airbrush. Now what? Well we need to figure out what type of line we are going to use and how far are we going to the work station. Or maybe you prefer it to be close by.

This is one of the many air compressors that we have that supply air to the pneumatic equipment and valves. This compressor are rated at 300 psi. The reason that I'm telling you all of this is because I have seen some of the members asking about how to set up there compressor. And since I have some experience with this maybe I can share what I know with every one, this is my way of giving back to the community. So let's start by saying that we just got a new compressor and it is not set up for an airbrush. Now what? Well we need to figure out what type of line we are going to use and how far are we going to the work station. Or maybe you prefer it to be close by.

Any way that all need to be taken in to account. We will explain as we go on. Let's start by what type of air line yo want to use. There are many one. But we're just gone mention just a few. Let's start with black pipe the most commonly use. You can purchase this at any hardware store and it's sold in increment of inches or feet. But the one thing that I find sometime is that if you need a specific length you will end up having to do it in section. Or you can try and find a store that will cut it and retreaded. To the exact length that you need. Then you will need other tools that you may not have like pipe wrench or Chanel lock. Or what ever else you may need. The next one are cooper pipe or tubing. Ether one is a good choice if you know how to solder or suet the feting.

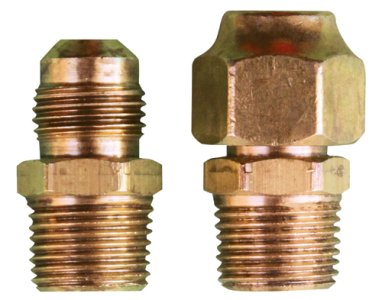

You can purchase this at any hardware store and it's sold in increment of inches or feet. But the one thing that I find sometime is that if you need a specific length you will end up having to do it in section. Or you can try and find a store that will cut it and retreaded. To the exact length that you need. Then you will need other tools that you may not have like pipe wrench or Chanel lock. Or what ever else you may need. The next one are cooper pipe or tubing. Ether one is a good choice if you know how to solder or suet the feting.  But with tubing you will need ether a compression feting or a flare feting . This is a compression fitting

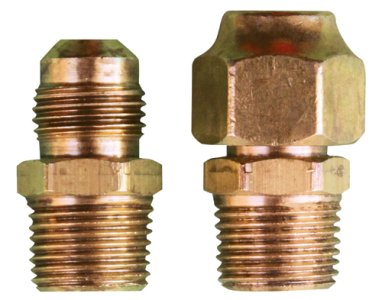

But with tubing you will need ether a compression feting or a flare feting . This is a compression fitting  the next is a flare fitting

the next is a flare fitting  For this type of fitting you need to flare the tubing and you will need a special tool for it, you can buy it at any hardware store. This is the tool.

For this type of fitting you need to flare the tubing and you will need a special tool for it, you can buy it at any hardware store. This is the tool.  When you flare it it should look like this

When you flare it it should look like this  and here is my favor Rapid Air

and here is my favor Rapid Air  this cab be purchase or order through Menard, Lowes, Home Depo. I guess i cant post any more pic so ill come back with the rest a little later.

this cab be purchase or order through Menard, Lowes, Home Depo. I guess i cant post any more pic so ill come back with the rest a little later.

This is a small part of where I work.

This is a small part of where I work.  This is one of the many air compressors that we have that supply air to the pneumatic equipment and valves. This compressor are rated at 300 psi. The reason that I'm telling you all of this is because I have seen some of the members asking about how to set up there compressor. And since I have some experience with this maybe I can share what I know with every one, this is my way of giving back to the community. So let's start by saying that we just got a new compressor and it is not set up for an airbrush. Now what? Well we need to figure out what type of line we are going to use and how far are we going to the work station. Or maybe you prefer it to be close by.

This is one of the many air compressors that we have that supply air to the pneumatic equipment and valves. This compressor are rated at 300 psi. The reason that I'm telling you all of this is because I have seen some of the members asking about how to set up there compressor. And since I have some experience with this maybe I can share what I know with every one, this is my way of giving back to the community. So let's start by saying that we just got a new compressor and it is not set up for an airbrush. Now what? Well we need to figure out what type of line we are going to use and how far are we going to the work station. Or maybe you prefer it to be close by.Any way that all need to be taken in to account. We will explain as we go on. Let's start by what type of air line yo want to use. There are many one. But we're just gone mention just a few. Let's start with black pipe the most commonly use.

You can purchase this at any hardware store and it's sold in increment of inches or feet. But the one thing that I find sometime is that if you need a specific length you will end up having to do it in section. Or you can try and find a store that will cut it and retreaded. To the exact length that you need. Then you will need other tools that you may not have like pipe wrench or Chanel lock. Or what ever else you may need. The next one are cooper pipe or tubing. Ether one is a good choice if you know how to solder or suet the feting.

You can purchase this at any hardware store and it's sold in increment of inches or feet. But the one thing that I find sometime is that if you need a specific length you will end up having to do it in section. Or you can try and find a store that will cut it and retreaded. To the exact length that you need. Then you will need other tools that you may not have like pipe wrench or Chanel lock. Or what ever else you may need. The next one are cooper pipe or tubing. Ether one is a good choice if you know how to solder or suet the feting.  But with tubing you will need ether a compression feting or a flare feting . This is a compression fitting

But with tubing you will need ether a compression feting or a flare feting . This is a compression fitting  the next is a flare fitting

the next is a flare fitting  For this type of fitting you need to flare the tubing and you will need a special tool for it, you can buy it at any hardware store. This is the tool.

For this type of fitting you need to flare the tubing and you will need a special tool for it, you can buy it at any hardware store. This is the tool.  When you flare it it should look like this

When you flare it it should look like this  and here is my favor Rapid Air

and here is my favor Rapid Air  this cab be purchase or order through Menard, Lowes, Home Depo. I guess i cant post any more pic so ill come back with the rest a little later.

this cab be purchase or order through Menard, Lowes, Home Depo. I guess i cant post any more pic so ill come back with the rest a little later.