tatocorvette

Mac-Valve Maestro!

Hello,

I recently completed the refurbish and clean up of this baby. As we have discussed before, the history of the airbrush is sadly under-documented. To me, a big part of this hobby is researching and learning about the history of the topic. I've been researching this one for weeks but there is not much information out there. This is what I have been able to gather from different sources. If anybody has more details, or if there is anything wrong with this information, by all means PLEASE let me know.

Badger started out as a supplier (machine shop) doing contract work for airbrush manufacturers like Thayer and Chandler and others. The founder of the company suggested some product improvements to Thayer and Chandler but these were rejected. Eventually, Badger started producing their own airbrushes in 1964 with the help of ex-Thayer and Chandler employees. The first product was the Badger 100XF which is essentially based on the Thayer and Chandler's Model A. I haven't found specific evidence but I would think there was some sort of collaboration between the companies, more than just "we'll make something similar to yours".

Despite been a high quality product, Badger sales were not very successful at the beginning as the market was slow to accept a new player. That's when a Testor's hobby company employee suggested Badger to cater to the hobby market. Around 1966 Badger introduced 2 new airbrushes oriented to scale model hobbyists: The low cost Badger 250 (very basic and simple external mix miniature spray gun, still in production today) and the mid range Badger 200: A quality single action internal mix airbrush capable of managing enamels and automotive lacquers. These 2 models helped Badger become a successful player in the market.

Here is where the story becomes convoluted.

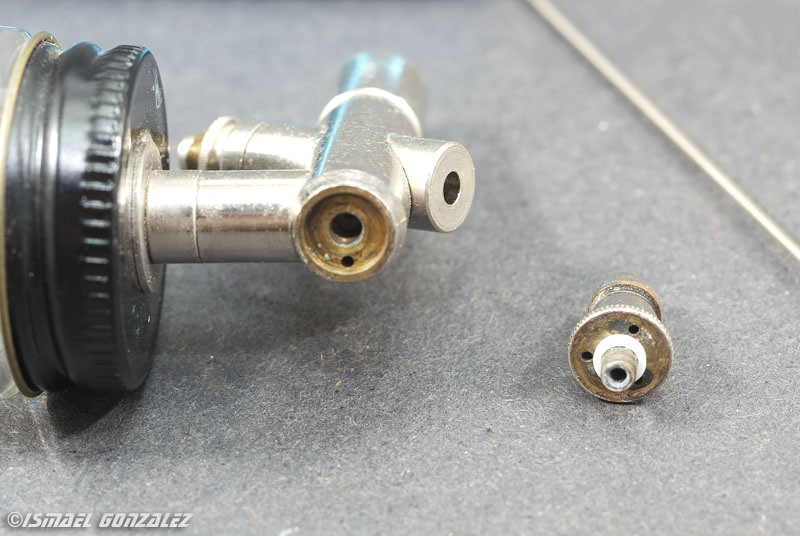

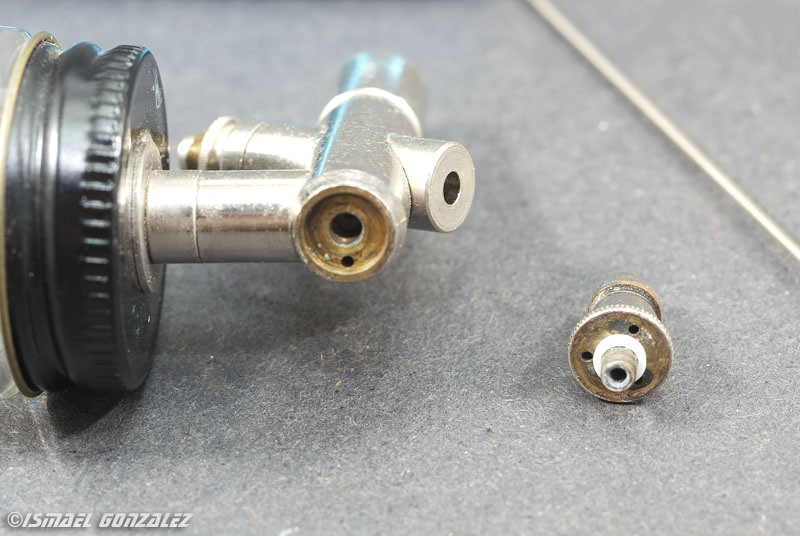

The Badger 200 is still in production today. The current Badger Model 200 is available in 4 versions: NH, 20-Detail, SG (Gravity feed cup) and G (no cup gravity feed). These are all evolutions of the original design. However, you will find documentation referring to an "old style 200". You may think it was a single original version. However, I have found 2 different "old style" models. The difference is that the most common one has the well known friction siphon tube where you connect either a jar or a color cup. That is one of the most distinctive features of siphon feed airbrushes to this day. That's what the current NH and Detail models have. However, the one I have, and others I've seen online, can only work with paint jars as they use a screw type lid adapter (pictures below). But to make it even more confusing, I have found online evidence (pictures) showing both type bodies sharing the same part numbers despite been physically different. That makes me think they were not made concurrently, but rather it was a production change at some point. But was the screw jar the original? I found online a documented unit with the original sales receipt from 1969 (matching serial numbers) , clearly showing the screw lid design. So I would think that was the original design, and eventually it was changed to the friction siphon we know today.

But wait there's more: In my research, I found a 1976 SEARS catalog offering the airbrush with the "later style" siphon friction tube, but the same catalog from 1977 shows the screw jar unit! Same price on both. Keep in mind SEARS rebranded many items from many manufacturers and did not carry the original manufacturer's names. The documented offering from 1969 shows a flyer indicating the deluxe kit 200-3 was $26.95. You'll see on mine the price was $29.95 for the same Deluxe kit part number, so it was definitely later than 1969.

So the story still has many gaps. Quite a mystery!

Anyways, this is what I got:

No dates anywhere. Printed material like the useful guide usually have a print date but nothing here. The illustration of the airplane is showing a Vietnam era cammo scheme. So I think this should be early 70's. The cans may still have some pressure left

Seems to be pristine.

However, taking it apart showed signs of use and long term storage.

To the left you can see how the paint is delivered. Very different to the slanted friction tube we know. Some "aggressive negotiations" were required to remove the lid adapter.

Everything was properly brought back to life.

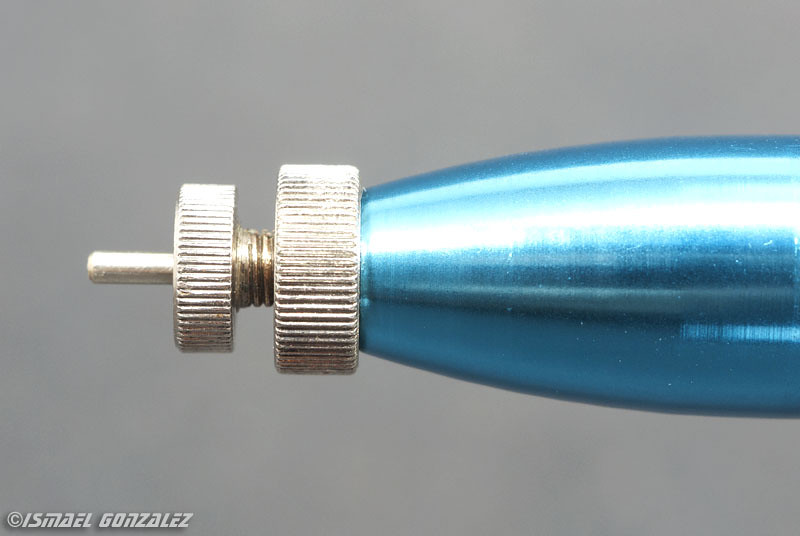

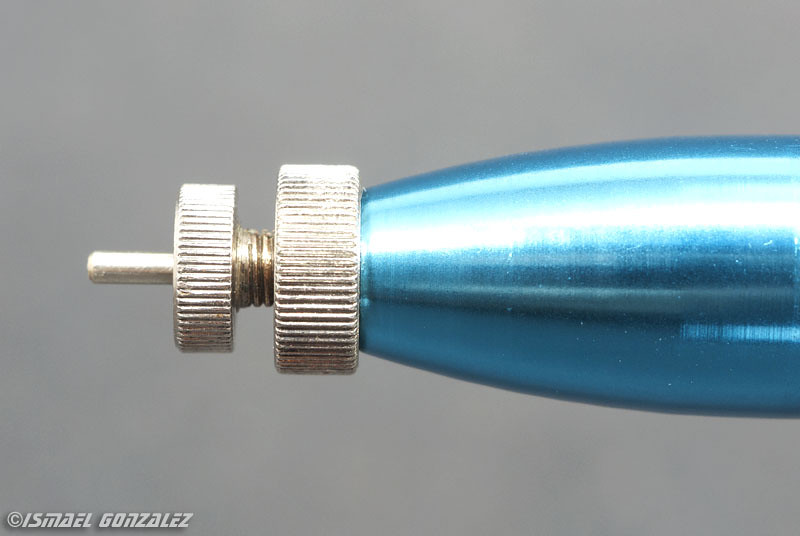

The needle received special attention as it was quite bad, polishing it with 1200, 2400, 3200, 4000, 6000, 8000 and 12,000 grit polishing pads followed by metal polish. I love how it turned out.

After this picture was taken the black lid was cleaned and polished to a like new condition. Also the head/nozzle/regulator tip was finally submitted to obedience by force as it was really, Really, REALLY stuck. I was able to finally take it apart (non-destructively ) and deep clean everything.

) and deep clean everything.

May I present my new Badger 200 which is about the same age as I am

Still needs a proper real life test but initial bench test look ok.

Hope you like it.

What do you think?

Sorry for such a long post.

Thanks,

Ismael "the Badger fan"

I recently completed the refurbish and clean up of this baby. As we have discussed before, the history of the airbrush is sadly under-documented. To me, a big part of this hobby is researching and learning about the history of the topic. I've been researching this one for weeks but there is not much information out there. This is what I have been able to gather from different sources. If anybody has more details, or if there is anything wrong with this information, by all means PLEASE let me know.

Badger started out as a supplier (machine shop) doing contract work for airbrush manufacturers like Thayer and Chandler and others. The founder of the company suggested some product improvements to Thayer and Chandler but these were rejected. Eventually, Badger started producing their own airbrushes in 1964 with the help of ex-Thayer and Chandler employees. The first product was the Badger 100XF which is essentially based on the Thayer and Chandler's Model A. I haven't found specific evidence but I would think there was some sort of collaboration between the companies, more than just "we'll make something similar to yours".

Despite been a high quality product, Badger sales were not very successful at the beginning as the market was slow to accept a new player. That's when a Testor's hobby company employee suggested Badger to cater to the hobby market. Around 1966 Badger introduced 2 new airbrushes oriented to scale model hobbyists: The low cost Badger 250 (very basic and simple external mix miniature spray gun, still in production today) and the mid range Badger 200: A quality single action internal mix airbrush capable of managing enamels and automotive lacquers. These 2 models helped Badger become a successful player in the market.

Here is where the story becomes convoluted.

The Badger 200 is still in production today. The current Badger Model 200 is available in 4 versions: NH, 20-Detail, SG (Gravity feed cup) and G (no cup gravity feed). These are all evolutions of the original design. However, you will find documentation referring to an "old style 200". You may think it was a single original version. However, I have found 2 different "old style" models. The difference is that the most common one has the well known friction siphon tube where you connect either a jar or a color cup. That is one of the most distinctive features of siphon feed airbrushes to this day. That's what the current NH and Detail models have. However, the one I have, and others I've seen online, can only work with paint jars as they use a screw type lid adapter (pictures below). But to make it even more confusing, I have found online evidence (pictures) showing both type bodies sharing the same part numbers despite been physically different. That makes me think they were not made concurrently, but rather it was a production change at some point. But was the screw jar the original? I found online a documented unit with the original sales receipt from 1969 (matching serial numbers) , clearly showing the screw lid design. So I would think that was the original design, and eventually it was changed to the friction siphon we know today.

But wait there's more: In my research, I found a 1976 SEARS catalog offering the airbrush with the "later style" siphon friction tube, but the same catalog from 1977 shows the screw jar unit! Same price on both. Keep in mind SEARS rebranded many items from many manufacturers and did not carry the original manufacturer's names. The documented offering from 1969 shows a flyer indicating the deluxe kit 200-3 was $26.95. You'll see on mine the price was $29.95 for the same Deluxe kit part number, so it was definitely later than 1969.

So the story still has many gaps. Quite a mystery!

Anyways, this is what I got:

No dates anywhere. Printed material like the useful guide usually have a print date but nothing here. The illustration of the airplane is showing a Vietnam era cammo scheme. So I think this should be early 70's. The cans may still have some pressure left

Seems to be pristine.

However, taking it apart showed signs of use and long term storage.

To the left you can see how the paint is delivered. Very different to the slanted friction tube we know. Some "aggressive negotiations" were required to remove the lid adapter.

Everything was properly brought back to life.

The needle received special attention as it was quite bad, polishing it with 1200, 2400, 3200, 4000, 6000, 8000 and 12,000 grit polishing pads followed by metal polish. I love how it turned out.

After this picture was taken the black lid was cleaned and polished to a like new condition. Also the head/nozzle/regulator tip was finally submitted to obedience by force as it was really, Really, REALLY stuck. I was able to finally take it apart (non-destructively

May I present my new Badger 200 which is about the same age as I am

Still needs a proper real life test but initial bench test look ok.

Hope you like it.

What do you think?

Sorry for such a long post.

Thanks,

Ismael "the Badger fan"