BullBuchanan

Young Tutorling

Hey all,

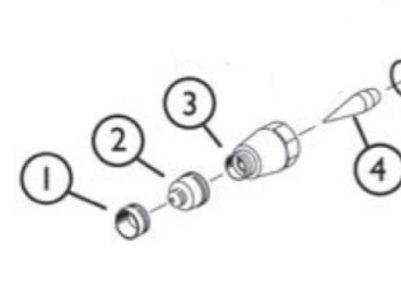

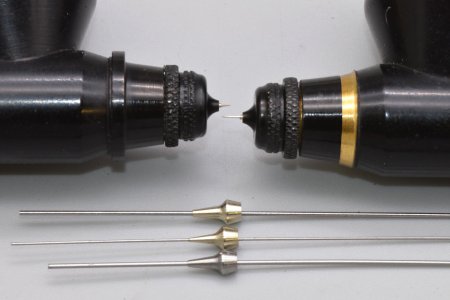

I'm a fairly novice airbrush user focused on painting miniatures and over the last two days I've had two nozzles on two different airbrushes (Patriot 105 and Iwata eclipse get ruined - one split and one flared) by the spring loaded mechanism that pushes against the airbrush sticking in the compressed position and then working free which shot the needle forward and overextended through the nozzle.

With the badger it happened while I was cleaning primer out of my cup and with the Iwata it happened as I was testing the trigger after a full teardown, clean and reassembly after acquiring it yesterday. This is an expensive and massive headache.

In the year or so I've been airbrushing, I think this is responsible for all of my damaged nozzles. Has this happened to anyone else and what did you do to prevent it?

I'm a fairly novice airbrush user focused on painting miniatures and over the last two days I've had two nozzles on two different airbrushes (Patriot 105 and Iwata eclipse get ruined - one split and one flared) by the spring loaded mechanism that pushes against the airbrush sticking in the compressed position and then working free which shot the needle forward and overextended through the nozzle.

With the badger it happened while I was cleaning primer out of my cup and with the Iwata it happened as I was testing the trigger after a full teardown, clean and reassembly after acquiring it yesterday. This is an expensive and massive headache.

In the year or so I've been airbrushing, I think this is responsible for all of my damaged nozzles. Has this happened to anyone else and what did you do to prevent it?