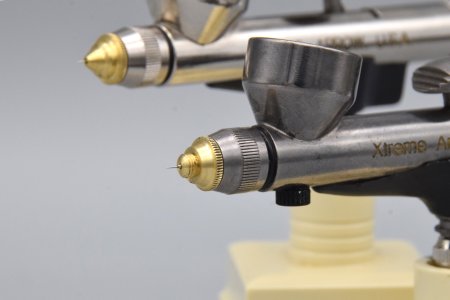

That is pretty wild. I just assumed it was done that way to allow easier cleaning of tip dry. Looking at it now that I have more airbrushes to compare to. The nozzle does stick out a crazy distance from the body.I actually did quite a bit of work with the Patriot, and Patriot Arrow several years ago. Between the original version of the Xtreme and later versions I found a manufacturing alteration that basically killed the brushes true potential. I think one of the reasons people find Tim's version so easy to do detail with, is that it is a brush that only works at about 60 or 70% of it's true potential/capability.

If you are on FB, I have a bit up a write up I did a few years ago -

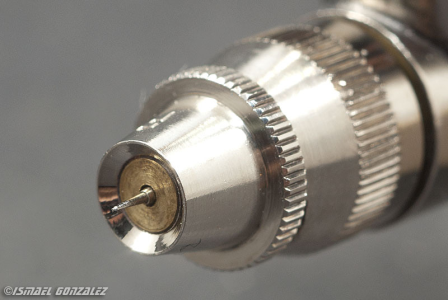

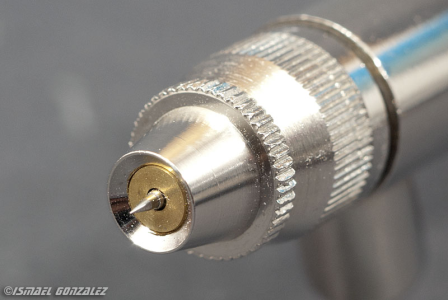

If you're not on FB - the first versions of the Patriot Xtreme had an air cap that exposed the needle all the time. Enough people complained about damaging the needle tip that they revised the air cap to include a reversible needle cap. When they made the revision they changed the specs of the cap buy enlarging the exit bore, and lengthening the amount of nozzle exposed at the front. The new dimensions are nowhere near as efficient at doing what they are supposed to do and it really crippled the brushes performance. The original exposed cap design was awesome. I made a few similar versions of my own testing stuff out, but lost interest in working on them...

Looking at my Patriot and Patriot arrow next to each other. It is kind on crazy that bore for the air cap on the .3 on my arrow is larger than the bore for the .5 on the Patriot.

This does explain why it has been such a trip trying new airbrushes. Used my arrow so much before. Put it away during my ADD adventure and now see what I have been comparing them all to now.

Guess I will just stick with the medium Sotar for general work.

Not to further your distraction. But I have a extra non extreme patriotic arrow and super detail kit. If you want one to do experiments with.