Such a stand would be ridiculously expensive to buy.

I wonder how much? You can calculate such a things

I think your liquid nails type glue would be fine.

Sikaflex is good but probably overkill.

Will search for you proposal.

OK, so it's going to be glued with that type.

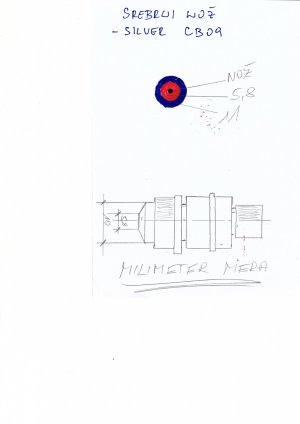

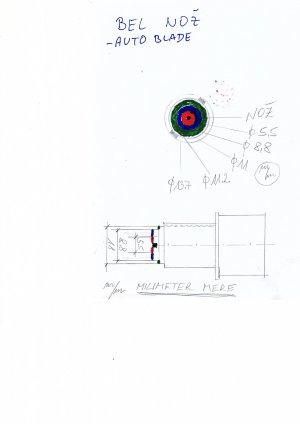

There are lots of generic cb09 holders and all price levels of the blades for them....most are very good.

They are a whole world apart when upgrading from cameo type and much better than the plastic Roland type. Metal Roland is probably close but I still think the graphtec is better for the way the load is put on the blade inside the holder.

I have three types of Roland types of the holders and many dozens of the blades. It seems now that there's nothing to improve in the blades, but I'm not satisfied with the blade holders. Mine are good, their bodies are made with the plated aluminum. So I have plans to make more prices one. Need to buy some special tools I don't have, I mean diameters I don't have, the tools I do have.

As I've already said, I'll think over making smth to the plotter carriage to increase precision, besides the blade holders. You may say what am I going to do with one of the best inexpensive machines, but I am what I am

I see that some thing can be better.

Vladimir, You will get your measurements tomorrow. Talked with my old man right now on a phone, and he sad to me I need to explain something in person.I will go to him tomorrow after the launch, when I will pick machine for drilling walls at his place.

I'm not in a hurry at all. Thanx!

But to be on topic, when I asked him yesterday to do the measurements, he asked me how much those blade holders cost. I told him like 10 bucks. He

looked at me confused, and asked me why that guy wanna do his own holders if they are so cheap?

I started to laugh and told him: I don't know, maybe he's cheap bastard like I am

And you the cheap bastard? I've bought mine good quality for 7 bucks each and I know where to have them (identical to what I have) at 4, I just didn't want to pay 40 bucks for 10 blade holders

You cheap bastard!

The question is to make precise holder, more precise that I have. Maybe the one I have are great, but they can be better. Time will show waht I'll come up with.

From my test cuts of the vinyl I'm satisfied with the outcome, but the best is the enemy of good!

I'll behave now Vladimir, I just love this channel -.-

Great channel!

You know guys, any man is a bit that Russian inside, especially you

@huskystafford if you have Slavic nationality

If I'd tell the story how in my childhood I was trying to make the rocket... When I was trying to launch it I almost sh@it my pants, but if I'd continue my story you'd wet yours, besides you'd fill your rooms with the tears from laughing adding some hitting your keyboards with your heads

I'll spare your keyboards.

So I mean, I like the channel much!

Lol ! When I was 19 I took some car rims and welded steel beams on them ... Cut up and going across the width so I have steel paddle wheels.

Worked great until I drove along ruts that had been made by a tractor, filled with water and froze over. My wheels went right through the 60mm ice and I was stuck until spring.

Cool!

If I'd have the tools in that age of yours, you'd see my stuff, if I'd be alive now after my experiments

I once get to the hospital for over a week after experimenting with some little home made bomb

Yes, I think 99 is just a setting on the cutter not pounds of pressure, and single path/single cut/1 pass, cuts through what thickness I have no problems. I've tried 125 micron and its ok but its a little too thin/flimsy, 190 micron is much better and is a reasonable thickness for shields, doesn't flop about so much. The 250 micron will be perfect if I can cut it. The 30 and 45 deg blades work fine but I found the 60 deg can cut a tighter line.

I have cut my own shapes in the 190 and also some commercial ones like the Fibonacci spiral, bird, pharaoh, "h" and some of the b-fast shapes.

I am planning on doing them again but this time smaller scale so I can use them on PP's and smaller paintings. I have most of the available stencils saved as files on my pc. Just cut them if and when I need one. I've also got several large and small true fire shields I brought from a guy on eBay called Deltaarts in Poland, they seem thicker than my 190 so I guess it could be 250 micron.

Lee

It's bad when the manufacturers make different setting to the tools, we can't know that exact pressure we do to the blade holders. Mine have grams of down pressure.

Thought I haven't tried 120 micron at work, but I totally agree with you, it's no good for the any relatively bigger shields. As I've said, it may be good for curved surfaces like tanks, etc. This thickness feels almost like random office paper. In some cases it's great.

Your down pressure is the beast! You will definitely cut in double, triple cut, I think.

I also have cut the shield you've mentioned, but with an e-acto

I did not have even the plans to have the plotter then.

BTW, what program do you make your vector graphics in for the shields?

this was done with cb09 holder and those graphtec blades on that mylar which I posted before:

OMG!

If your Cameo can do this, than what my beast with the servo motors could do?

BTW, I'll show you what I've done without the plotter similar to this stencil of yours just to remind you of the channel you've mentioned!

I need to glue my feed tables as fast as I can to try my stuff! Men, you're inspiring me!